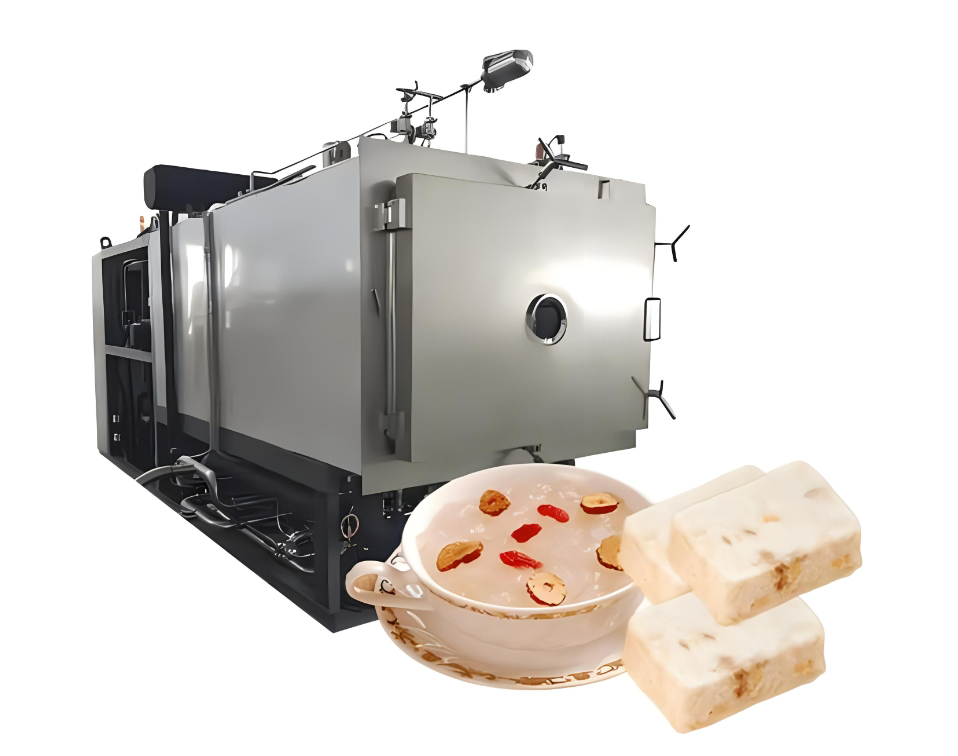

Shensheng Bird’s Nest Freeze Drying Machine (Bird’s Nest Freeze Drying Machine) is a stable dehydration and drying equipment in the manufacturing industry. Using a bird’s nest freeze dry machine to freeze bird’s nest raw materials at low temperatures, and then directly sublimating the solid ice in a vacuum environment to remove gas, and making bird’s nest freeze-dried bird’s nest fragments, instant bird’s nest, freeze-dried silver ear bird’s nest, and other products, thereby extending the shelf life and service life of bird’s nest. This article introduces the structure, principle, application, and advantages of bird’s nest freeze dry machine, which facilitates the understanding and use of bird’s nest freeze-drying products and equipment.

The bird’s nest freeze dry machine is composed of a freeze-drying box (including a material warehouse and a water trap), a refrigeration system, a vacuum system, a circulation system, a hydraulic system, an electrical control system, etc. The PLC electrical control system can perform automatic or manual operations such as low-temperature refrigeration, vacuum control, circulation temperature control, rubber plug capping, freeze-drying process control, etc.

The principle of bird’s nest freeze dry machine is based on the coexistence or conversion of three states of water: liquid, solid, and gas under different temperatures and vacuum environments. The working principle of a cosmetic freeze dry machine is to freeze a substance below the eutectic point at low temperature into a solid state, and then through vacuum and low pressure, the solid ice is not melted and directly sublimated into water vapor to remove it, leaving behind a solid substance with nutritional activity.

The bird’s nest freeze dry machine can be used in the bird’s nest manufacturing industry for freeze-dried bird’s nest fragments, instant bird’s nest, freeze-dried silver ear bird’s nest, and other freeze-dried processing applications. Throughout the entire processing, it is carried out in a low temperature and vacuum environment, which can protect the nutritional active ingredients of cosmetics, prevent oxidation and chemical reactions, and have advantages such as minimal water content after freeze-drying. This can extend the shelf life of cosmetics, facilitate transportation and storage, facilitate use, increase stability, and improve production efficiency.

The application of cosmetic freeze dry machines in the cosmetics industry has the advantages of shortening drying time, ensuring the service life of bird’s nest, improving the production efficiency of cosmetics, and being convenient to use. At the same time, it reduces labor costs during the production process, facilitates storage and circulation, improves cost-effectiveness, provides bird’s nest value, and enhances the quality and market competitiveness of bird’s nest.